Industry 4.0 concept (also identified as fourth industrial revolution, smart industry or cyberindustry of the future) corresponds to a new way of organising means of production. The overall aim is to iniciate a large number of "Smart factories" capable of a greater adaptability to the requirements and means of production, as well as a more efficient allocation of resources, thereby opening the way to a new industrial revolution or Fourth Industrial Revolution.

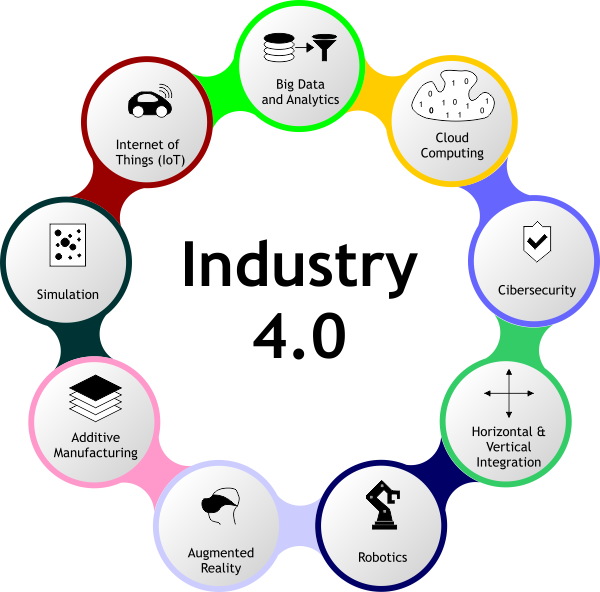

The technological basis which that current of thought is supported are, among others, the following: (1) Internet of Things; (2) Cyberfisic systems; (3) Maker culture (Do-it-yourself culture); (4) Factory 4.0, etc.

Industry 4.0 is consistent with the so-called Fourth Industrial Revolution, emphasizing and accentuating the idea of an increasing and adequate digitalisation and cooperative coordination in all productive units of the economy.

Why 4.0.

From a technological point of view, the following industrial stages can be distinguished in history:

- 1.0 (18th Century): Mechanical production using water and steam as source of energy.

- 2.0 (Early 20th Century): Mass production based on the division of labour and using electricity as source of energy.

- 3.0 (Since the 70s): Use of computer technology and electronics for an improvement in automation of production.

- 4.0 (Nowadays): Interconnected production systems, elaboration of analysis and decision making process based on real-time collected data.

How can Creatio help you. Cómo te ayuda Creatio

Creatio helps you advising and implementing monitoring and data storage technologies, analysis, project design for installation of components: sensors, actuators, PLCs Reading, ERPs, etc, in a way that integrates different systems in a factory: productive, HR, energetic, etc.

Creatio te ayuda en el asesoramiento e implementación de las tecnologías de monitorización y almacenamiento de datos, análisis, diseño de los proyectos para instalación de componentes: sensores, actuadores, lectura de PLCs, ERPs... de forma que se integren los distintos sistemas de la fábrica: productivo, RRHH, energéticos, etc...

English (UK)

English (UK)  Español (ES)

Español (ES)  Italiano (IT)

Italiano (IT)